Upload time:2025-07-25 09:01:39Clcks:

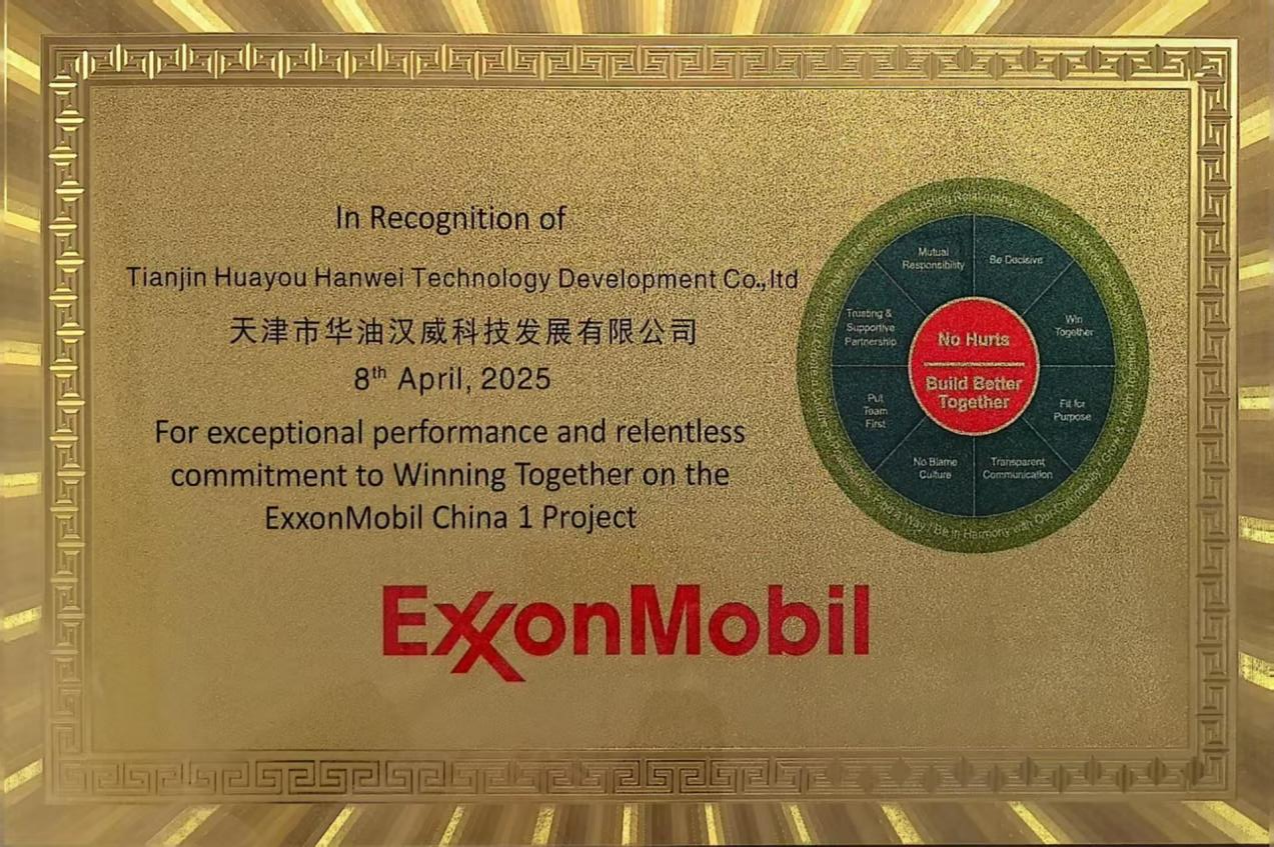

Recently, Tianjin Huayou Hanwei Technology Development Co., Ltd. (referred to as "Huayou Hanwei") has successfully completed a large number of valve pressure testing and pre-commissioning maintenance services for the ExxonMobil Huizhou Ethylene Project with professional and efficient services, providing a solid guarantee for the smooth progress of the project. As a result, it has been awarded the "ExxonMobil Outstanding Collaborative Quality Service Award". This award aims to recognize "Huayou Hanwei" for providing high-standard valve pressure testing and maintenance services during the safety assurance and successful start-up phases of the Mobil plant. This honor not only represents the high recognition of our company's professional service capabilities by an international chemical giant, but also marks that the service capabilities of Chinese local valve maintenance enterprises have been officially endorsed in international high-standard projects.

International-level Test: Building a Solid Safety Foundation with Technological Hard Power

Recently, the ExxonMobil Huizhou Ethylene Project has been put into operation. The first phase of this project includes a flexible feed steam cracking unit with an annual production capacity of 1.6 million tons of ethylene, as well as polyethylene and polypropylene production facilities with an annual capacity of 2.65 million tons. This project, as a major petrochemical project independently constructed by an American enterprise in China and one of the first seven major foreign-funded projects in the country, has a total investment of over 10 billion US dollars. It adopts the world's advanced low-carbon process and intelligent production technology. The safe start-up and stable operation of this project directly determine the demonstration value of the industry benchmark project. Among them, valves, as key components for fluid control, directly affect the safety production and stable operation of the entire project. Since taking on the related business of this project, our company has attached great importance to it, established a special service team, strictly followed the project standards and norms, and formulated a detailed work plan.

During the valve pressure test phase, the team members conducted meticulous inspections on each valve to ensure that all indicators such as its pressure resistance and sealing performance met the design requirements. Before the start-up, during the maintenance work, they identified and resolved the faulty valves promptly, fully guaranteeing that the valves could operate stably during the project's start-up stage. Throughout the process, the team consistently adhered to the concept of "high-quality service and outstanding coordination", closely cooperating with the ExxonMobil project team, communicating efficiently, responding promptly to various needs, and winning the high recognition of the other party with their professional technical capabilities and strong sense of responsibility.

Emergency efforts demonstrate strength and ensure that the key valves are in place.

During the critical stage of starting up the ExxonMobil Huizhou Ethylene Project, a large-diameter valve (NPS36 CL300 gate valve) suddenly experienced internal leakage and jamming problems, directly threatening the progress of the plant's commissioning plan. In an urgent situation, ExxonMobil and Huo You Hanwei simultaneously activated the emergency response mechanism. Our company, as the core service provider, responded promptly and entered a "wartime state" overnight. Huo You Hanwei relied on the local spare parts warehouse at the Huizhou base and Carry out overnight planning and arrangement special sealing components, combined with laser cladding repair technology to handle the valve seat sealing surface. Finally, the commissioning and delivery were completed 4 hours ahead of schedule. The successful completion of this emergency task fully demonstrated Huo You Hanwei's professional and efficient service capabilities in valve maintenance. For this reason, our company was highly recognized by the ExxonMobil project and was specially awarded an honorary medal by us.

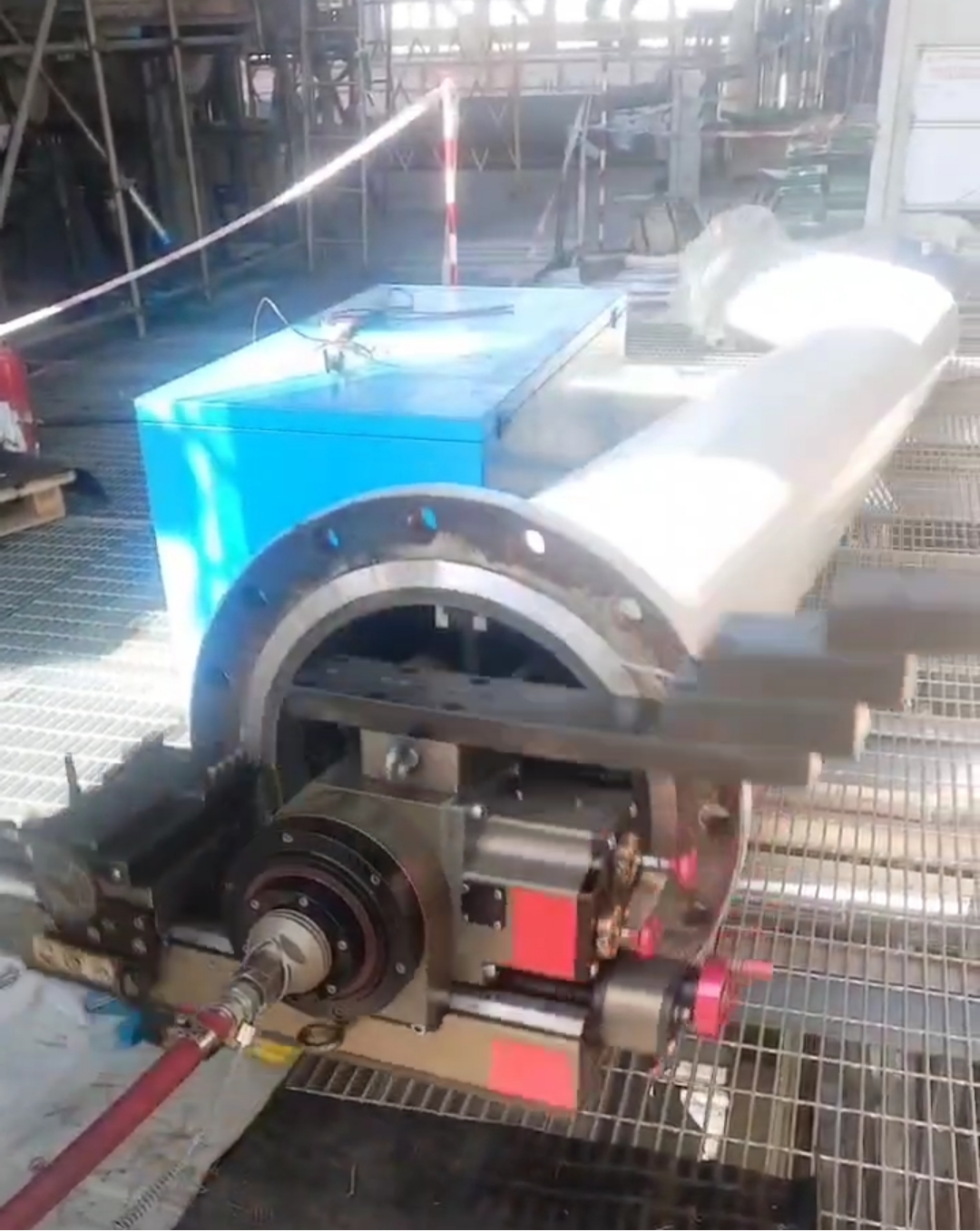

Online Flange Processing Demonstrates Its Capabilities, Precise Repair Project Advances

Apart from emergency repairs of critical valves, during the critical phase of the project, some flanges on-site suffered varying degrees of damage and water line wear due to frequent operations during the installation and commissioning process. These seemingly minor flaws, if not promptly addressed, could lead to medium leakage and affect the sealing performance in the case of minor issues, or could potentially cause safety hazards due to pressure imbalance in the case of more serious problems, directly hindering the smooth commissioning of the equipment.

In response to this situation, our company promptly responded to the demand and dispatched a technical team equipped with professional online flange processing equipment to the site. The team, based on the degree of flange damage and the on-site conditions, formulated a targeted repair plan: using a portable flange end face processing machine, without disassembling the flange, they performed ** milling and grinding on the damaged surface to quickly restore the flatness of the flange sealing surface; for the problem of water line wear, they reprocessed the sealing water line using special tools to ensure that its fit with the gasket met the sealing standards.

Throughout the entire process, the technicians remained at the site throughout, communicating the progress with all parties of the project in real time, and controlling the processing accuracy with their superb skills. Eventually, they successfully completed the repair of all the damaged flanges. These online processing services not only avoided the delay in the project schedule caused by the disassembly of the flanges, but also ensured the sealing and safety of the pipeline connection with "zero error" repair quality, laying a solid foundation for the smooth progress of the subsequent pressure test and start-up procedures of the project, once again demonstrating our company's professional strength in on-site emergency repair.

This award is not only a recognition of our company's service quality in this project, but also an endorsement of our company's professional technical strength and collaborative spirit. In the future, our company will take this as an opportunity to continue to deepen its focus on the valve service field, and continuously improve to provide higher-quality and more reliable services, contributing more to the development of the industry.